Climate Action

Our Vision for BlueScope in Australia

Our vision for BlueScope in Australia is to be a vibrant, modern manufacturer, embodying progress, innovation and sustainability.

Our approach

Climate action is key to Our Purpose and is a core element of our Corporate Strategy: building a pathway to low emission-intensity iron and steelmaking in Australia is a key priority for our business.

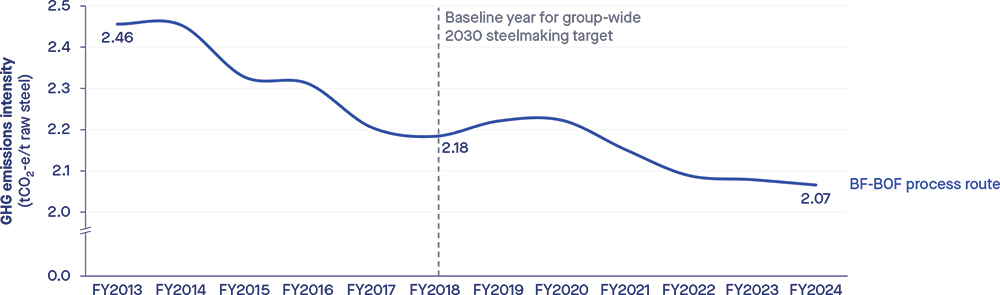

Our Performance – Port Kembla Steelworks

Port Kembla Steelworks is placed in the ‘top 15% Blast Furnace-Basic Oxygen Furnace performers’ (BF-BOF) for the emission intensity of blast furnace-based operations1. Between FY13 and FY24, the site's emission intensity has declined by 16% to 2.07 tCO2/tonne raw steel, well below the global BF-BOF average of 2.22 tCO2/tonne raw steel2. This is predominantly driven by a significant increase in scrap usage rates in the basic oxygen furnace, as well as higher operational volumes and improved process energy efficiencies.

1Worldsteel CO2 Data Report 2023 (2022 data year) has the Port Kembla Steelworks site in the lowest 15th percentile for emission intensity of BF-BOF steel plants. Note that this data is limited to those iron and steelmakers who voluntarily report on emissions data with worldsteel (56 BF-BOF sites in 2022 representing 17 per cent of global BOF steel production and 53 per cent of global BOF steel production excluding China. No Chinese steel plants report CO2 data to worldsteel).

2 Based on steelmakers who reported to worldsteel in 2023 (with 2022 data) where co-product production is applied to the BF-BOF routes considered.

Climate Action – global goal and targets

The following goal and targets apply to BlueScope’s global operations, including steelmaking and non-steelmaking operations in Australia.

^ Applies to our Scope 1 and 2 emissions, relative to a 2018 baseline, across our midstream or non-steelmaking activities

^^ The non-steelmaking target applies to our midstream activities that include our cold rolled, metal coating and painting lines and long and hollow products. It excludes our downstream activities.

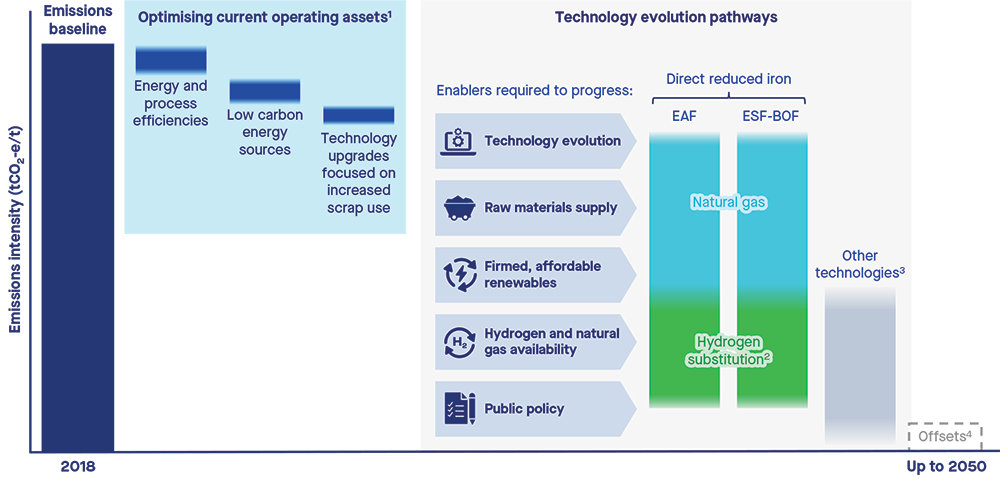

Australian decarbonisation pathway

Our Port Kembla Steelworks decarbonisation pathway outlines the steps we plan to take to meet our 2030 GHG steelmaking target and net zero 2050 goal, subject to the five key enablers listed above.

Indicative Decarbonisation Pathway - Port Kembla Steelworks

- Optimising current assets involves working within currently available technology options to improve the efficiency of assets and processes, including upgrading technology where there are supportive enablers. This continues beyond 2030 until such time as it is feasible to convert to lower emissions DRI technology. Continuous improvement principles will apply to future production processes.

- Contingent on commercial supply of hydrogen from renewable sources.

- Other technologies could include electrolysis, CCS and biocarbon etc.

- While we do not intend to rely on offsets as a primary means of decarbonisation, we retain the option to use them to meet our 2050 net zero goal where direct abatement is not technically or commercially feasible. Such decisions will be reviewed at the BlueScope Group level and are included in this site level indicative decarbonisation pathway to indicate that offsets may have a role to play.

Taking action in Australia

Optimising current operating assets

To meet our 2030 reduction targets, we’re continuing to optimise current operating assets across our Australian footprint.

Maximising the use of scrap steel at Port Kembla Steelworks remains a key focus. We increased scrap content in the steelmaking process from approx. 21.5% to 25.4% over the past 5 years1. Given its cooling effect, current levels of scrap in the steelmaking process are approaching their technical maximum limit. Our aim is to increase scrap content to 30% by 2030 by investigating ways to pre-melt scrap, along with a number of asset modifications. This additional scrap content has the potential to reduce emissions intensity by ~6%.

We are also trialling the use of biochar, produced from sustainable biomass. In 2023 we successfully conducted biochar trials at Port Kembla Steelworks, supported by ARENA2. In these trials we:

- Tested how biochar would perform as a replacement for Pulverised Coal Injection (PCI) coal in the blast furnace

- Achieved up to 30% PCI coal replacement.

We are currently working with several sustainable biochar supply projects within Australia, given there is no industrial scale biochar supply chain in Australia.

- For information on recycled content in BlueScope products, visit our Recycled Content page.

- This Project received funding from the Australian Renewable Energy Agency (ARENA) as part of ARENA’s Advancing Renewables Program. The views expressed herein are not necessarily the views of the Australian Government, and the Australian Government does not accept responsibility for any information or advice contained herein.

Long term to 2050: technology evolution pathway at Port Kembla

BlueScope is focused on developing a clear pathway to low emissions ‘primary’ steelmaking in Australia. We believe Direct Reduced Iron (DRI) is the most prospective technology to decarbonise our Australian business. We are investigating accelerated technology developments in natural gas Direct Reduced Iron (DRI) as a transitional pathway to using green hydrogen to produce lower emissions steel.

In February 2024, BlueScope announced a new framework agreement with Rio Tinto and BHP to accelerate the decarbonisation of steelmaking by jointly investigating the development of the country’s first ironmaking electric smelting furnace (ESF) pilot plant. In December 2024, the Kwinana Industrial Area, south of Perth, was confirmed as the location for the ESF pilot plant. For further information, please refer to the NeoSmelt update.

“We believe the development of ESF technology is key to unlocking Australia’s unique advantages in this decarbonisation journey – and, more importantly, has the potential for wider adaptation across the global steel industry. We believe that this collaboration where we can contribute BlueScope’s unique experience in operating an ESF will be key to cracking the code for Pilbara ores in low emission-intensity ironmaking.”

Tania Archibald, Chief Executive Australian Steel Products

Further information

- Visit bluescope.com/sustainability/climate-action

- Read more about Project NeoSmelt

- Watch the video to learn more about ESF and its role in low-emissions ironmaking: Electric Smelting Furnace (ESF): A Bridge to Low-emissions Ironmaking