BlueScope at TRANSFORM 2025 - Advancing Steel Decarbonisation

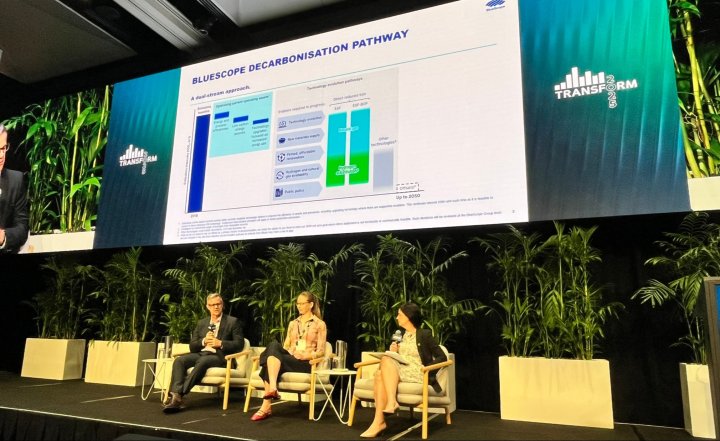

Panel discussion – accelerating Innovation in the Global Transition to Net Zero. Pictured are Chris Page (BlueScope), Alli Devlin (ResponsibleSteel™) and Davina Rooney (GBCA).

BlueScope was proud to be a Gold Partner of TRANSFORM 2025, the Green Building Council of Australia’s (GBCA) industry-leading sustainability conference, held on 19–20 March.

TRANSFORM brought together industry leaders, sustainability experts, and policymakers to explore key priorities, such as decarbonisation and transforming existing assets, to drive meaningful change across the built environment.

A key highlight was BlueScope’s participation in the panel discussion Accelerating Innovation in the Global Transition to Net Zero, where Chris Page, Head of Future Technologies at BlueScope, joined Alli Devlin, Decarbonisation Lead at ResponsibleSteel™, and Davina Rooney, CEO of GBCA, to discuss the challenges and opportunities in decarbonising steelmaking.

The need for global steelmaking decarbonisation

With 71% of global steel produced through the basic oxygen furnace (BOF) steelmaking route (primary steelmaking), achieving net zero requires a fundamental shift in iron and steel production methods. Chris Page highlighted the importance of primary steelmaking and why recycling alone cannot deliver the emissions reductions needed due to the demand for scrap outweighing supply.

He outlined how BlueScope’s innovative NeoSmelt project is exploring a potential pathway to lower emissions iron making using Australia’s abundant Pilbara ores. NeoSmelt will be Australia’s largest ironmaking electric smelting furnace (ESF) pilot plant, designed to test a groundbreaking technology that produces iron without relying on traditional blast furnaces. In partnership with Rio Tinto and BHP, BlueScope is developing the NeoSmelt pilot plant in Kwinana, Western Australia, which is set to produce up to 40,000 tonnes annually by 2028.

This large-scale pilot has the potential to scale directly to commercial production. While BlueScope is focused on decarbonising the Port Kembla Steelworks, the NeoSmelt project is recognised as world-leading and has the potential to shape the decarbonisation of global steelmaking.

ResponsibleSteel™: A global standard for sustainable steel

Alli Devlin, Decarbonisation Lead at ResponsibleSteel™, highlighted the importance of fostering collaboration to drive the transition to near-zero emissions. “The transition requires strong partnerships. By working with companies who are on the right track, such as BlueScope, we can drive meaningful change across the sector,” she said.

BlueScope is proud to be a founding member of ResponsibleSteel™, the first global, independent, multi-stakeholder standard and certification program for the steel industry. With over 160 members, including 30 steelmakers, ResponsibleSteel™ provides a certification standard that aims to accelerate the industry’s transition to net zero while ensuring consumers can be confident that the steel they use has been sourced and produced responsibly.

BlueScope reinforced its commitment to sustainability and responsible steelmaking through its ResponsibleSteel™ site certifications. Port Kembla Steelworks achieved ResponsibleSteel™ certification in early 2022, becoming the first site in the Asia Pacific region and the fourth globally to achieve this recognition. Our Western Port site followed in October 2023.

BlueScope products and Green Star

At the BlueScope stand, our team engaged with attendees, sharing insights into key product credentials and certifications, including Environmental Product Declarations (EPDs) and ecolabels. They also showcased how these are recognised by leading green building rating tools and schemes, including Green Star.

The Green Star Responsible Products Framework recognises a range of initiatives that products or manufacturers can comply with to contribute to Green Star certification. BlueScope products may contribute to a projects Green Star rating through several initiatives, including ResponsibleSteel™ site certification, Environmental Product Declarations (EPDs), and Global GreenTagCert™ GreenRate™ certification. Many of our industry-leading brands, such as COLORBOND® steel for roofing and walling, are classified as Best Practice Products. For more information, download our Green Star Responsible Products Framework brochure.

A shared commitment to a low-carbon future

TRANSFORM 2025 provided an invaluable platform for knowledge-sharing and collaboration. As we continue exploring solutions to reduce emissions in steelmaking and enhance transparency through initiatives like Environmental Product Declarations (EPDs), BlueScope remains committed to driving innovation. We are focused on working with customers, industry partners, policymakers, and sustainability leaders to achieve transformative change.

Reflecting on the event, Philippa Stone, Sustainability Manager at BlueScope highlighted the value of industry-wide collaboration, “TRANSFORM 2025 reinforced the need for collective action on climate change, particularly across the steel value chain. Our commitment to ResponsibleSteel™ and investments like Project NeoSmelt demonstrate BlueScope’s commitment to decarbonising our operations and advancing the decarbonisation of the steel sector more broadly,” she said.

Learn more about our ResponsibleSteel™ certification, climate action projects like NeoSmelt, download our Environmental Product Declarations (EPDs), and see how our product credentials and certifications can be recognised by Green Star.