Architect Drew Heath's mountain bike-inspired bush retreat combines the brutal posturing of prosaic shipping containers with the refined elegance of a soaring lightweight steel roof.

When it was first mooted, the concept for this base camp was not nearly so refined and daring, according to builder Daniel Girling-Butcher. "The client approached me in March 2013 and said he'd bought this property and was interested in putting some shipping containers – which he'd chosen for budget reasons – on the site," Girling-Butcher explains. "I mentioned this to Drew, boasting somewhat in the pub about this job that had fallen into my lap, and Drew showed some interest. He gave the project quite a lift."

Heath saw an opportunity to take the 'building blocks' and create something remarkable. He contacted the clients to outline his scheme. "That same day, I did a sketch and emailed it to the clients, trying to invite myself into the job. They liked it, so I managed to muscle in on the project.

Heath suggested that a sandstone outcrop near a cliff top was the best place to build. "To me it just said 'footing': we could anchor a building onto it and do something that was adventurous, structurally," Heath says

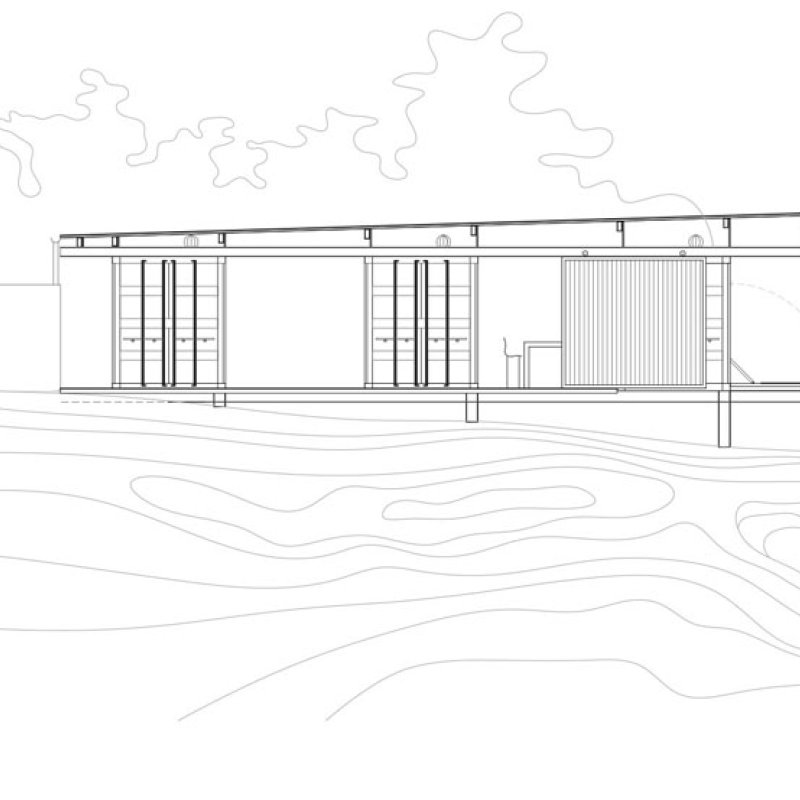

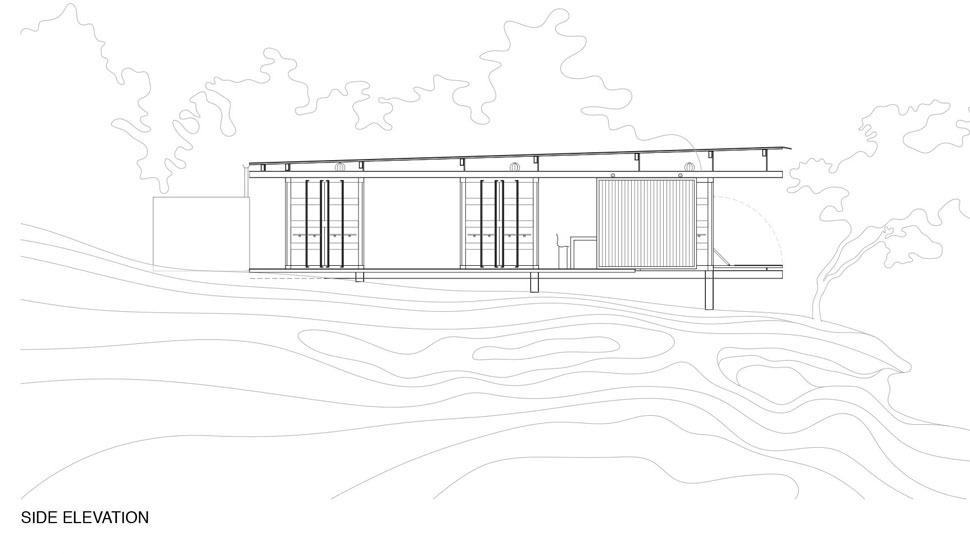

He carefully arranged three containers in one line to make the outlook over the gully and bush the hero. "The site has an orientation that looks out to a great view, which also has a northerly aspect, so that seemed the place to start," he says. "I had a very simple scheme in the back of my mind: an image of a boat ramp with two singular tracks that head off into landscape, with a floating roof above.

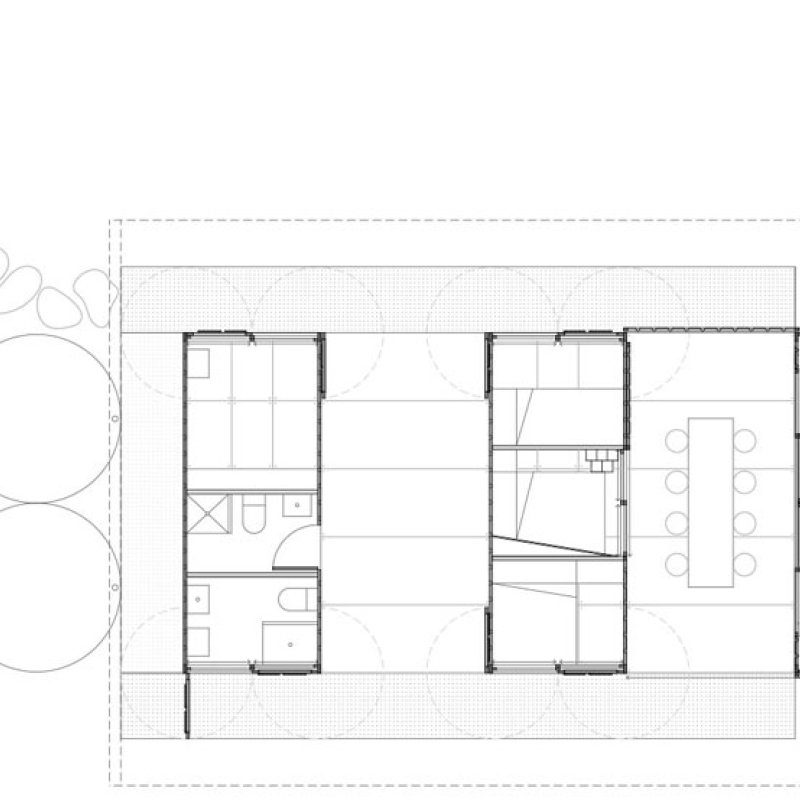

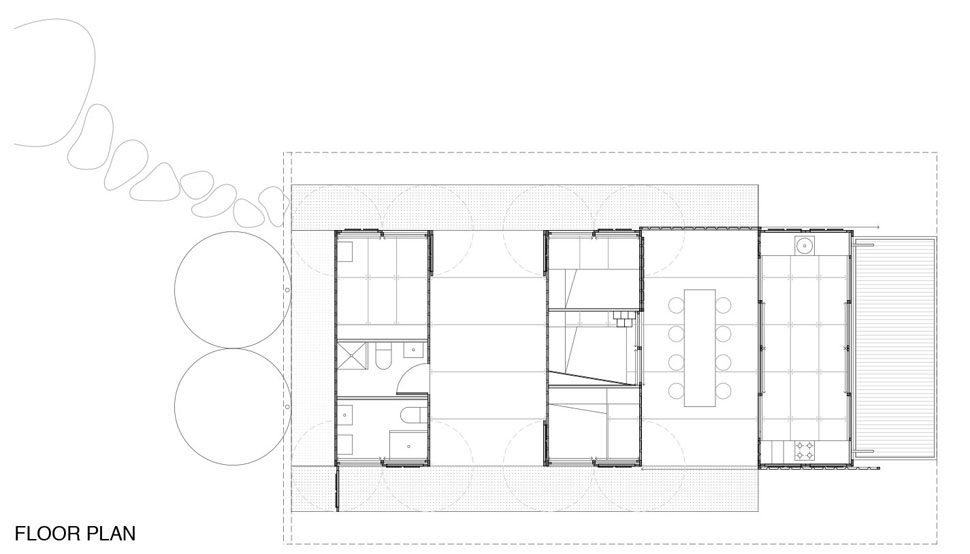

"To satisfy the brief for more space, I just kept adding containers behind the first one, to accommodate bedrooms, bathrooms and storage, and then inserted spaces in between for outdoor rooms.

The inherent qualities of the containers dictated the selection of materials for the whole project, he says. "Once I'd seen the containers purely as steel boxes, I was determined to make every external element steel."

Each of the containers was reconfigured with new openings and doors to suit their position in the project. The front unit – which contains the kitchen – has the largest openings, including a cantilevered deck on hydraulic hinges that closes to seal the container from the elements. It has sliding doors, opposite that connect to a dining space. The sides of these can be enclosed by steel shutters on rollers.

Heath said the ability to close down the building against the elements was important, given its vast bush surrounds. The fire risk at the location led us straight to steel. Being able to lock down the structure entirely with steel was a big consideration in terms of bushfire performance.

The central container houses three bedrooms, with pivoting doors at both ends and a sliding door in the middle, while the rear container boasts two bathrooms and a storage space.

Having outlined his concept to Girling-Butcher and steel fabricator Brett Laker, the building was constructed in an unusually fluid manner. "Luckily Daniel and Brett are people I know well and they know my work, so we didn't have to do a lot of detailing or drawing," Heath says. "A lot of it was spoken word, and a few sketches and images to convey the information.

"It's nice to be flexible from concept to finish, and to not be so dogmatic about detailing every single part," he adds. "It makes things easy." The containers were largely fitted out in a warehouse in Botany in Sydney while the steelwork was prefabricated at Laker's factory on the Central Coast.

The elements were then trucked to site and assembled over a 10-day period leading up to Christmas in December 2013, with final touches completed over several weeks in January 2014. The structural steel supports – six 200 UC 46 sections – were drilled into the sandstone and secured with concrete footings. Beams were installed, then the shipping containers were craned on to the southern end of the platform and winched outwards to their final positions. Steel walkways were installed as the outer decks on the long sides. The roof frame – 200 UC 46s and RHS acting as purlins – was then topped with roofing made from COLORBOND® steel in LYSAGHT KLIP-LOK® 700 profile, in the colour Ironstone®.

The KLIP-LOK® profile roof – chosen for its wide spans and ability to be installed at low pitch – provides direct protection from the sun and rain, and also allows cross-flow breezes to draw hot air out of the containers because it is raised slightly above a series of ventilation points in the top of each box.

The building came together so easily that the second time Heath visited the site, Outpost 7427139 as it's now called – after the serial number on one of the containers – was practically complete. It may be modest in size – just 40m2 internally – but it sleeps six and has two bathrooms. It is fully self-sufficient: collecting and storing rainwater in three tanks, generating and storing sufficient solar power to run a small fridge, LED lights, and treating wastewater in a septic system located slightly down the slope.

While the concept may be simple – steel platform, steel shipping containers, steel roof – there is a refined elegance to its execution that sits comfortably alongside the building's brutal posturing. "I see this scheme as an aggressive construction. The big cantilevers of the deck and the roof give the building a sense of aggression, like it is perching on the edge of the cliff, ready to leap off," he continues. "But the spans and the overhangs are comparatively lightweight. The structure is simple and although this is a low-budget building, there is a sense of elegance in its simplicity."

Unorthodox it may be, yet the building is an elegant metaphor for mountain biking. Sitting on the cantilevered deck taking in the broad sweep of the valley is akin to taking up position on a mountain bike saddle, at the top of a hill, ready to hurtle down into the unknown.