Cool Rooms: Award winning student accommodation

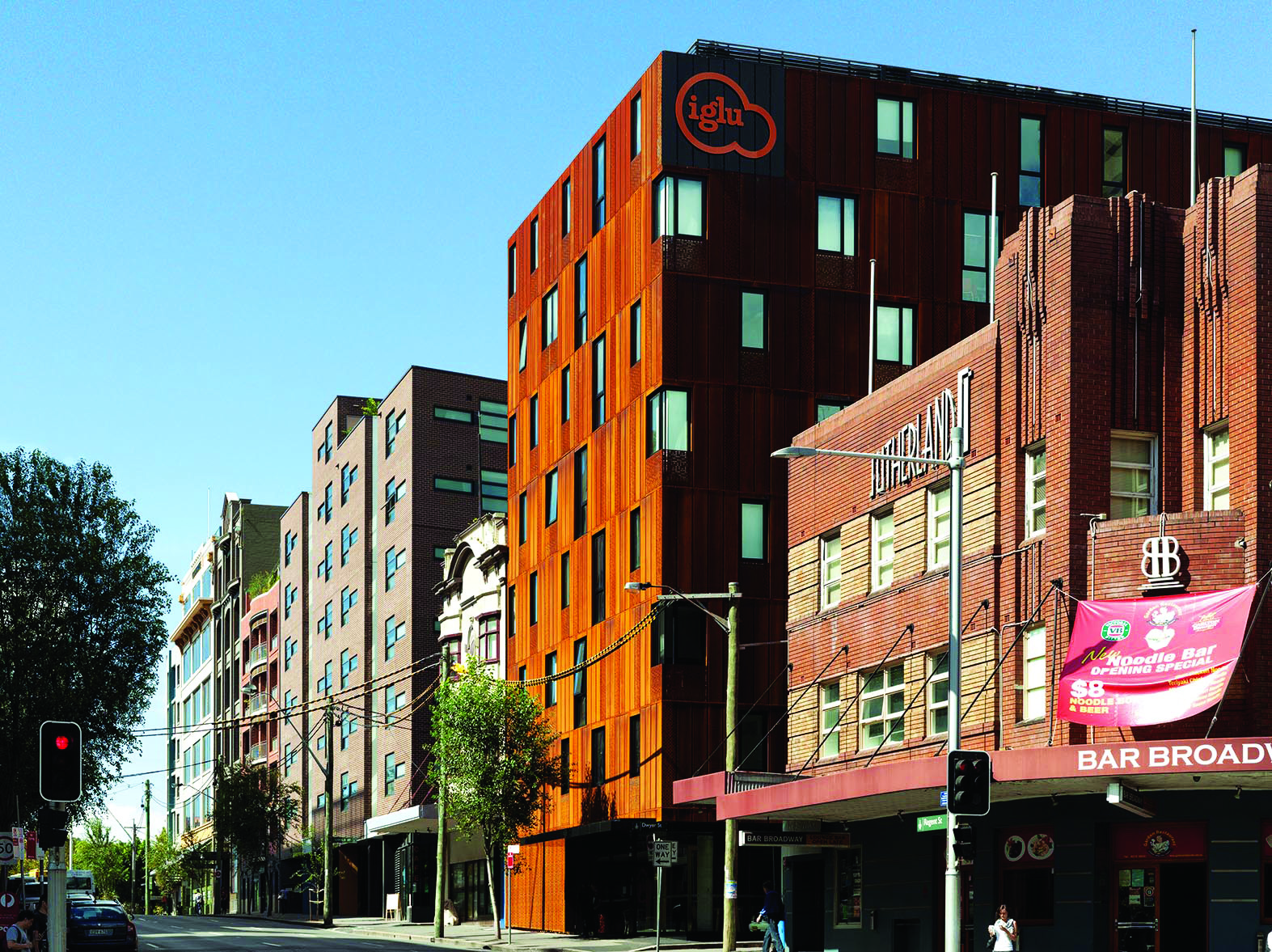

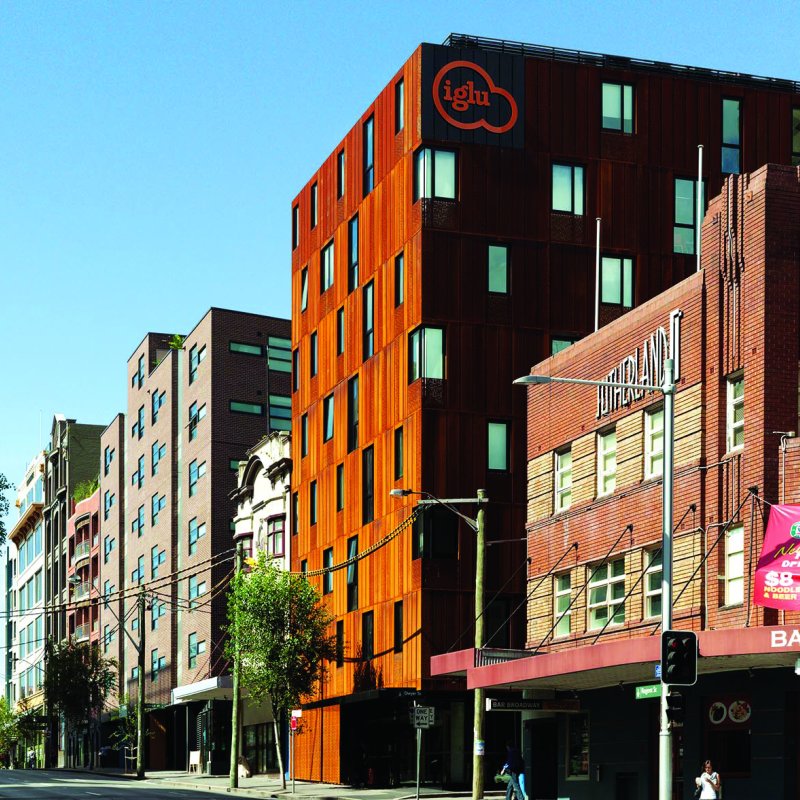

Drawing on experience from several previously completed multi-unit residential and student accommodation projects, Bates Smart director Guy Lake has honed a design solution to arrive at the most efficient typology possible, without compromising on quality or finish. On a tight corner block on busy Regent Street, adjacent to the Central Park development and a stone’s throw from Sydney’s Central Station and several university campuses, Lake and his client wanted this eight-storey, 100-bed facility to have its own distinctive presence.

“This is Iglu’s first building in Sydney, and they wanted to make it a landmark project,” Lake says. “The market for student accommodation is becoming a lot more sophisticated and Iglu was keen to create a brand that appealed to both local and overseas students

“Our brief was to design a ‘hotel for students’ and to consider all the details about how the rooms work in exactly the same way we would approach a hotel project,” he adds. “But they have tight budgets, so one of the key aspects is to get the planning to be incredibly efficient: that’s a critical part of the design process.”

Guy Lake, Director, Bates Smart

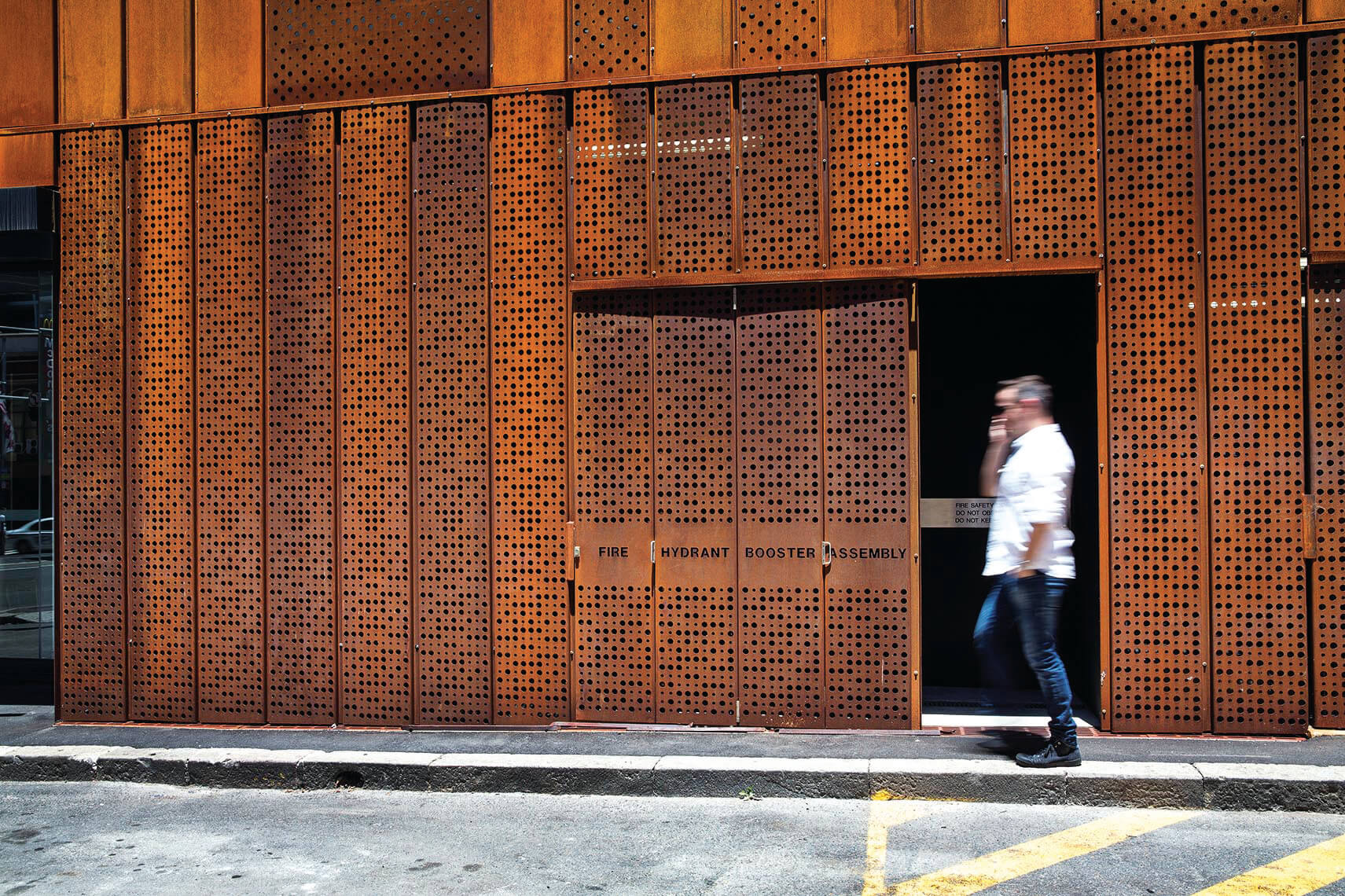

Given the small size of the site, the dual street frontages, and the character of the streetscape, Lake opted for an L-shaped plan that abuts the footpath. “It’s clearly a block-edge precinct, with a strong context of brick buildings and a history of industrial uses,” he says, “so we chose REDCOR® weathering steel for the cladding to pick up the colour of the brick without imitating it, and also to reference the industrial history of this area”.

The cladding, made from REDCOR® weathering steel in the steel grade HW350A, was also chosen to give the building a striking identity, and for its low maintenance requirements.

"One of the differences between this and a strata residential building is that Iglu is the long-term owner, so maintenance is an issue that is taken seriously,” Lake says. ;

Having made the decision early on to clad the building in weathering steel, the custom-sized panels dictated the dimensions of the repetitive modules that impart a rational appearance. “Once we knew we were using this material, the whole building was set out on the 450mm module,” Lake says. “It ties in with the rooms – the windows are either 900mm or 1350mm wide – so it all fits together in a modular way.”

“That was the most efficient way to use a (1200mm-wide) coil, once you have folded the fixing edges,” Lake says. “We minimised the amount of wastage, which was critical to being able to afford this material, so it’s a very rational building. In student housing especially, you can’t afford frivolous things: this is a business and you need to come up with the most efficient outcome, but also something that provides a strong architectural response.”

To counter the risk of the facade appearing too regimented, Bates Smart alternated the placement of bedroom windows from left to right, in what Lake describes as “a very pragmatic response to building codes.” “If you have full-height windows on a building under 25-metres tall, which is not sprinklered, you need a 900mm separation vertically between floors,” he explains. “So here, the windows are staggered to allow us to have full-height windows without that vertical separation. Also, because the student housing typology is very repetitive, the staggering helps to break down what would otherwise be a very gridded and regular building.”

Contradicting misconceptions that weathering steel might be an expensive or difficult material to build with, Lake says the simplicity of the modular construction method allowed it to be completed on time and within budget.

“From a cost perspective, this project had to be delivered at the same cost as other student accommodation projects. It was very easy to scaffold this building and achieve economies with the steel facade system.”

Guy Lake, Director, Bates Smart

Lake says the waterproof sarking layer, which encloses internal plasterboard and insulation, was completed early in the build, allowing the internal fitout to be carried out before the facade was added. “The facade was one of the last elements to be finished on the project, and the screws used to affix the weathering steel were somewhat contentious,” he laughs. “Ideally we would have liked them to also have been weathering steel, or black, but that wasn’t practical. So, they are visible, but they are an honest expression of how the system works.”

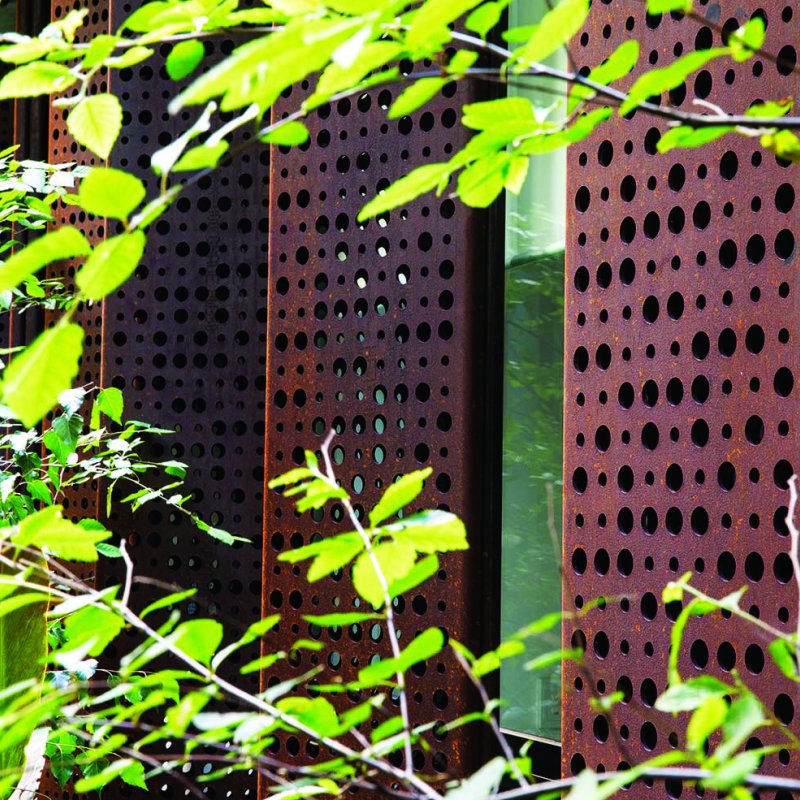

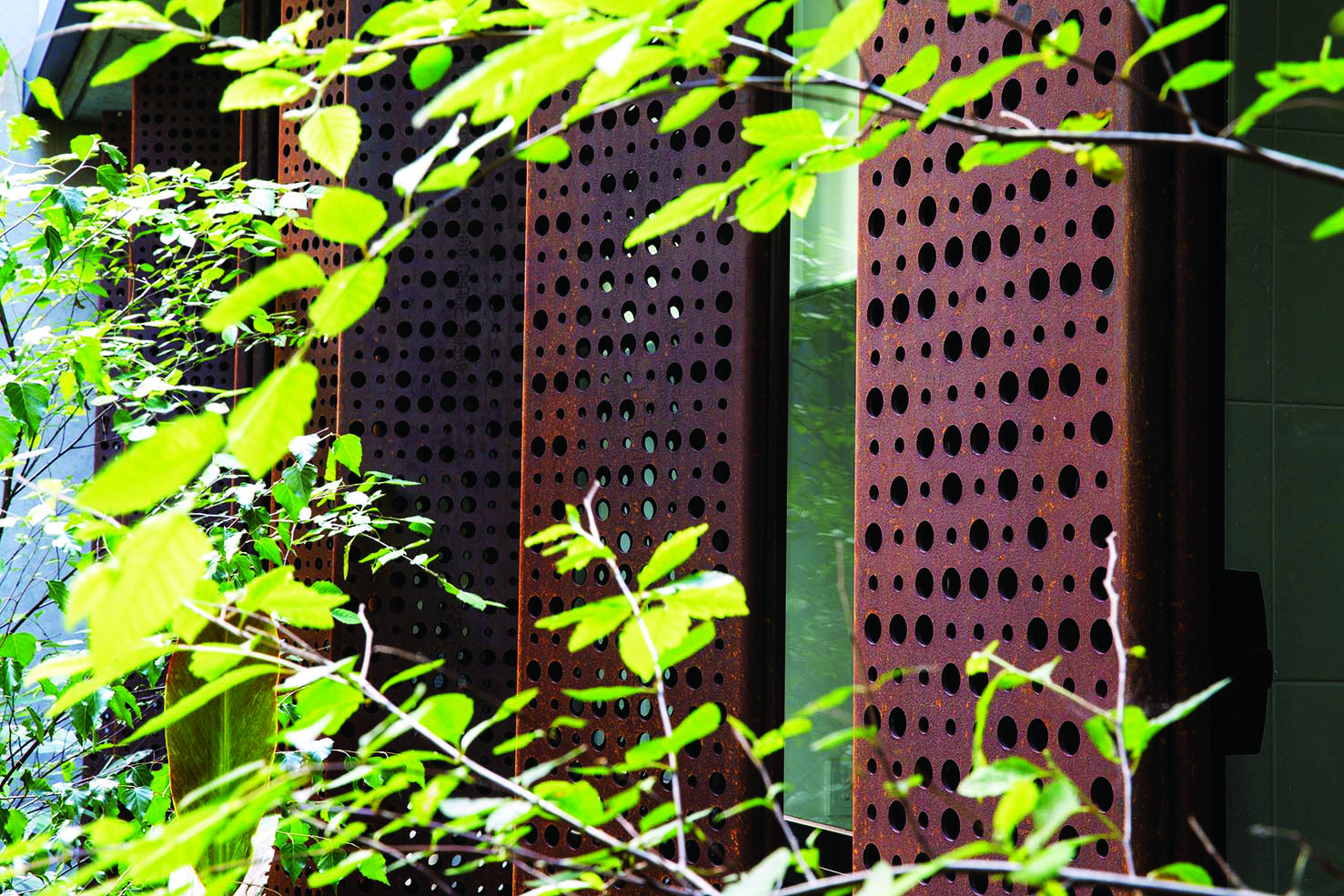

The use of perforations in some of the steel panels adds a degree of privacy while maximising natural light internally within the communal spaces at ground level and the bedrooms on the upper floors.

“A lot of the neighbouring buildings have fully glazed bases that try to be inviting from the street but don’t respond well to this block-edge street condition, or to what’s effectively a harsh urban environment,” Lake says.

“The challenge for us was to design living spaces behind the facade at ground level that were not disconnected from the street, but that offered a screen or protecting device. We also wanted to make the building feel grounded, and so bringing the weathering steel to the ground and cutting perforations in the panels allowed us to do that.”

On the Regent Street frontage, the perforated steel screen conceals the lounge and dining areas in the foyer, while on Dwyer Street the perforated steel doors provide natural light and ventilation to the rubbish and recycling room and bicycle storage facilities at ground level.

The ‘L’-shaped building encloses the internal courtyard on the ground floor where students can eat and socialise in a retreat away from the traffic and noise.

Standing in the leafy southern courtyard, overlooked by bedrooms above, Lake admits it’s not the obvious location for an indoor-outdoor room. “But it does provide a sanctuary from the street, and throughout the year sun does penetrate this space, and we clad it with lighter-coloured materials to maximise the light,” he says. “I’m told this space is incredibly well used. Our client is very interested in creating opportunities for students to engage and collaborate with each other, so we have created different seating options within a relatively small footprint, here and inside, to foster community among residents.”

Upstairs, there are three bedroom types: single rooms with ensuites and single rooms that share a ‘Jack and Jill’ bathroom, which are clustered into six-bed apartments with their own kitchen/living/ dining space, and self-contained studio apartments that occupy the north-east corner of each floor.

The perforated weathering steel cladding was key to balancing the need for light, space and privacy. “Upstairs, the rooms are relatively small so full-height windows make a huge difference to one’s sense of space, but there are privacy issues that go along with them, so we’ve introduced a ‘modesty’ panel of perforated steel, which gives a sense of openness for the occupants,” he explains.

“Combined with internal blinds, it allows them to control privacy, light and views in their own living environments.”

Always conscious of maximising the lettable area, Bates Smart minimised circulation and service zones: all of the ‘apartments’ are accessed via one lift or stair, and one short hallway on each floor, and the bathrooms and kitchens are stacked vertically. “One of the biggest issues in designing multi-residential buildings is getting those bathroom and kitchen exhaust services out,” Lake says. “They often end up being very badly integrated onto the facade, so we’ve used full-height perforated steel panels to conceal the service cores rather than using internal riser space, which we didn’t have room for in our overall floor plan.”

The same minute approach to detail is evident in the bedrooms, which are designed by the Bates Smart Interiors team, also responsible for the firm’s hotel projects. “We are trying to get the most rooms possible on the site but to still provide good amenities,” Lake says.

“While this has a student-type feel, the interiors are more resolved than typical student projects.” One of the most intriguing details can be found on the ground floor facade fronting Dwyer Street, where a unique gutter made from folded REDCOR® weathering steel works in conjunction with grates in the footpath edge to minimise run-off. “These gutters, which we’ve never used before, are having some impact on the way the building weathers, which is interesting,” Lake says. “What we really love about this material is that it changes all the time. So does the (Bates Smart-designed) Queanbeyan NSW Government Services Centre building, which I’ve revisited many times and looks quite different each time. With age, this colour will probably sit more and more comfortably with the surrounding brick.

“When it first went on, the client said to me that it looked like Uluru, which they loved,” he says. “From a branding and identity perspective, it’s a building that gets people’s attention, so while I think it’s very contextual, it also has a presence and identity. As a result, it’s generated a huge amount of interest and has really helped to position the Iglu brand.”

Guy Lake, Director, Bates Smart

These factors were all noted by the New South Wales Australian Institute of Architects Awards jurors last year, when they gave the building the COLORBOND® Award for Steel Architecture and an Architecture Award in the Residential Architecture – Multiple Housing category. In the words of the jury: “It is exciting and delightful to see steel extended in such a creative and expressive manner to deliver a remarkable addition to the fabric of the city. Fundamentally this material use gives the building personality and expression while allowing it to age and weather, delivering a richer building over time.”