Used in this project

- Products

- LYSAGHT LONGLINE 305®

- Materials

- COLORBOND® steel - Classic finish

- Colours

-

Clients drawing for their architect might sound zany, but it is one novel way of helping architect and client get onto the same proverbial page.

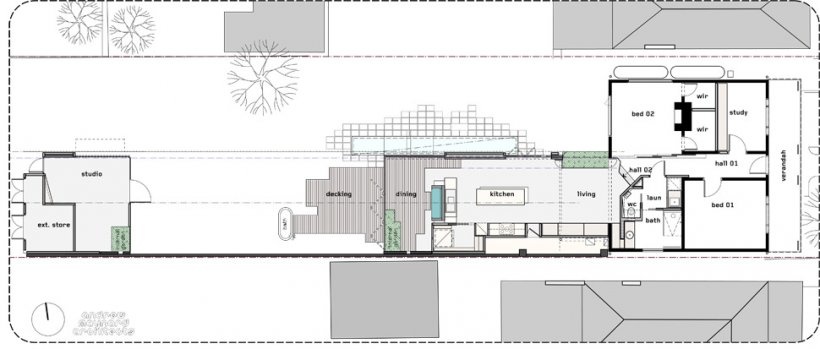

Melbourne architect Andrew Maynard says his client's brief for an addition to an original timber cottage asked for a solution that was "ridiculously inside-out". It offered a perfect brief for Maynard and his team, including project architect, Mark Austin.

Broken into a delicate structural rhythm, the addition flows from the original timber cottage to resemble a series of lightweight steel pods, or encampments, that reach deep into the backyard.

"Importantly we left the building incomplete," Maynard enthuses. "The central space, between the dining area and the studio, is an unclad frame within and surrounded by a garden. It is both inside and outside, a new building and an old ruin, garden and home.

"As a practice we often imagine what a finished building will become, but," he laments, "the magic of construction sites invariably ends in disappointment. Once houses are clad, the beautiful skeleton that held such potential and stirred the imagination is buried."

In contrast, the Cut Paw-Paw House retains a skeletal incompleteness that blurs at the edges and dissolves into its backyard setting, thanks to the exposed steel frame and the simple steel skin that punctuates its length.

The expressed steelwork of galvanised steel I-beams supports a cloak for all roofing and walls made from COLORBOND® steel Surfmist® in a Classic finish, in LYSAGHT LONGLINE 305® profile.

Off-site pre-fabrication involved workshop welding and bolting of various steel frames and components together, before dismantling them in the workshop and erecting them again onsite on a concrete slab and footings.

Maynard relishes steel's ability to stretch with his imagination. "From a detailing viewpoint we loved the long span and 0.7-millimetre industrial profile of LYSAGHT LONGLINE 305®. We're very interested in materiality and a return to craftsmanship that's possible with prefabrication and steel," he says.

In this case the clients' initial idea was the starting point for a journey that led to a thrilling result. "We really enjoyed responding to the idea of 'ridiculously inside out', and giving that unfinished appearance to the project," Maynard continues. "When the plants eventually consume the central part of the building, there's going to be a really lovely connection between that galvanised steel and the plants as they grab onto to it. The way the steel and the greenery will co-exist is going to become a beautiful little dance."