Used in this project

- Products

- LYSAGHT CUSTOM ORB®

- Fielders ARAMAX®

- Materials

- COLORBOND® steel - Classic finish

- Colours

-

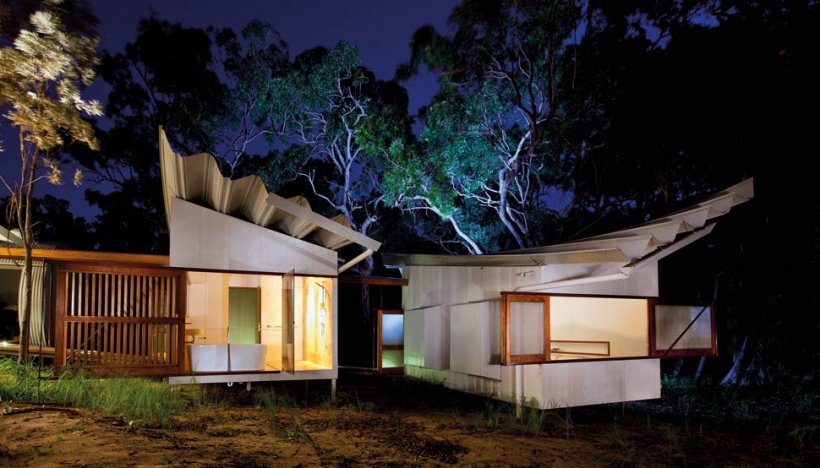

The cluster of steel pavilions Simon Laws designed for artist Marian Drew and her brother Derek sits on a forested dune above the beach in the gated estate of Sunrise at 1770, south of Gladstone, Queensland. In its dispersal of separate dwellings it is reminiscent of a campsite, and contrasts with some of its more grandiose neighbours in the enclave.

In the design of their beach house, the Drew siblings were keen to emulate childhood holidays spent camping in the region. “Marian and Derek had a strong connection to the site already,” says Laws. “It was clear from the start that we were to capture the feel of a campsite, but things then developed organically from our first visit there together.”

Something of the fragmented steel structures they discovered on a visit to their now-dismantled childhood home, ‘Fairymede’ (a sugar cane mill and processing plant outside Bundaberg), is apparent in the Drew house. When the Drews took Laws there to refresh memories, they found it in the process of being demolished. “There were amazing shapes to be seen everywhere – these big boilers and cane-cutting machines and turbines – all being dismantled,” says Laws.

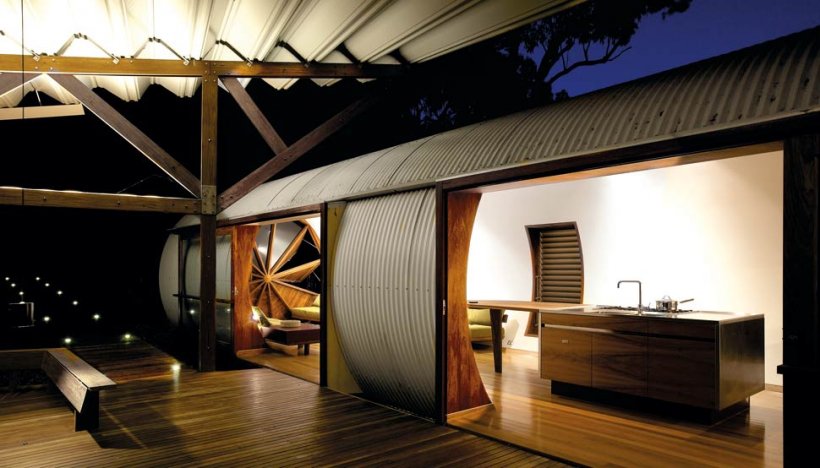

For their new house, a long tube of rolled corrugated steel – specifically CUSTOM ORB® profile made from COLORBOND® steel Surfmist® in a Classic finish – serves as the living zone and base station.

“The soft grey colour is also perfect in the bright sunshine. It blends with the surrounding bush of banksias, casuarinas and palms,” says Laws.

With a six-hour drive between the Gold Coast factory and its final destination, it was important to use lightweight, practical materials that were durable as well as being easy to assemble once on site. The two sleeping pods and the bathing pod are connected to the main living pavilion by a timber bridge that forms a central spine to the complex, hovering a metre above the sandy ground.

Their toothy, textured fibrous facades (“a nice link to the traditional weekender,” says Laws) are crowned with quirky, tilting roofs. The exuberant, zig-zagging roof is ARAMAX® profile made from COLORBOND® steel Surfmist® (in a Classic finish) which twists and lifts on the pods in opposing pagoda-like parabolas.

“ARAMAX® is a fantastic product with such a big spanning capacity,” says Laws. “I’d been wanting to use it on a project for some time. You can achieve these amazing cantilevers and spans in profile. It is light, durable and such good value. I love the way you can just spit out lengths of it on site.”

The elegant swoop of the awning – also ARAMAX® profile made from COLORBOND® steel Surfmist® in a Classic finish – on the northern edge of the living room tube sails from a lofty six metres at its highest point down to 3.5 metres at its lowest. Underneath, dining, wine drinking and star-gazing all take place around the home’s exterior hearth.

The gently twisting curves of the pods’ roofs lift their corners to look into the trees beyond. The pleasing aesthetic has a practical purpose too: lifting for increased ventilation. The northern wall of the bathing pavilion opens to the bush, and one of Marian’s photographic portraits of her daughter is emblazoned on the glass shower screen.

While the colour of the steel and fibro surfaces disintegrate and blend with the greys of the surrounding bush, richly stained timber doors and floors mimic the redness of the giant bloodwoods. And when the summer storms hit, the sound of rain drumming on tin recalls another magic moment from childhood.